The Importance of Sheet Metal Technicians in the Aviation Industry

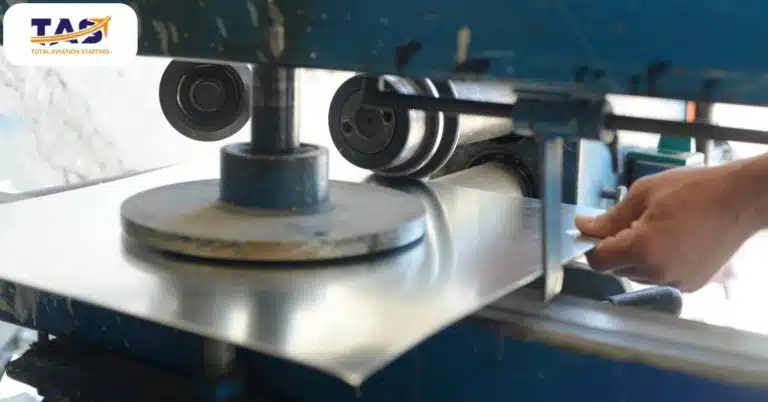

Sheet metal technicians are a critical part of the aviation industry. They play an important role in the manufacture and repair of aircraft parts. Without them, the aviation industry would come to a standstill. Sheet metal technicians are responsible for creating and repairing parts made from sheet metal. This includes everything from the wings and fuselage of an aircraft to smaller components like landing gear and control surfaces. They must be able to work with a wide variety of materials, including aluminum, titanium, and stainless steel.

1. Sheet Metal Technicians Are Responsible for the Installation and Maintenance of All the Metal Parts on an Aircraft

Sheet metal technicians are a vital part of the aviation industry, responsible for the installation and maintenance of all metal parts on an aircraft. They provide essential services to ensure aircrafts meet aviation standards and remain safe to fly. Sheet metal technicians use cutting-edge tools and materials to build high-quality aircraft components in accordance with aviation standards that must be met during the fabrication process. They also carefully inspect components for compliance to specifications and verify the consistency of fit, finish, and appearance before signing off on the work. By providing a reliable service from start to finish, sheet metal technicians guarantee airplane customers receive maximum satisfaction from their aviation experience.

2. They Play a Very Important Role in Ensuring That the Aircraft Is Safe for Flight

Sheet Metal Technicians are essential for aviation, as they play a pivotal role in ensuring the aircraft is safe for flight. They must expertly inspect, fabricate, and repair aircraft components from many different types of materials such as aluminum and titanium. This requires that technicians be highly qualified professionals who are able to locate and rectify any problems that may exist with the aircraft. Further, they complete visual inspections on the aircraft’s interior and exterior to verify whether it meets aviation industry standards. Their work can include restoring damage due to corrosion or other hazards that can impact airworthiness. These technicians ensure no detail is overlooked in maintaining aviation safety protocols and regulations so passengers can remain secure while travelling by air.

3. Without Sheet Metal Technicians, Planes Would Not Be Able to Fly

Sheet metal technicians are essential to aviation operations. They are responsible for building, maintaining, and inspecting the many components of aviation vehicles that make flight possible. Without sheet metal technicians, planes would not be able to take off as aviation relies on these highly skilled workers for constructing and repairing everything from wings and air frames to riveting and fastening. Their attention to detail is unparalleled – no error or structural defect goes unnoticed as they ensure that each aviation vehicle is up to the highest standards of safety set by the industry. Consequently, they play a critical role in aviation operations by helping protect passengers, crew members, and personnel on the ground in aviation-related activities.

4. They Are Responsible for Installing and Maintaining the Wings, Fuselage, and Other Metal Parts on an Aircraft

Sheet metal technicians play an invaluable role in the aviation industry. They are responsible for installing and maintaining all of the wings, fuselage, and other metal parts on an aircraft. Their work is incredibly important for the safety of passengers and crew. Without the skill and dedication of these technicians, aircrafts would be far less reliable and would not conform to aviation standards; therefore, potential aviation disasters would be more likely. As aviation technology advances increasingly complex systems are designed onto aircraft requiring skillful technicians who must have a clear understanding of the principles behind aviation engineering. Sheet metal technicians need to continuously stay up-to-date with their training so they can effectively install and maintain airplanes as aviation technology continues to develop.

5. The Work of a Sheet Metal Technician Is Critical to the Safety of an Aircraft

Sheet metal technicians are essential for aviation safety, given their critical role in repairing and maintaining aircraft. These skilled technicians not only have expertise in aviation-related sheet metal fabrication and installation, but also the ability to properly read and interpret aviation instructions and procedures. Through their experience and knowledge of aircraft, sheet metal technicians understand how important it is to have correctly installed parts that meet strict aviation industry standards. From inspecting components for corrosion and fatigue cracks to replacing panels requiring significant structural work, a sheet metal technician’s work is vital to ensuring an aircraft is safe throughout its flying life – from one flight to the next. With an attentive eye to detail and adherence to rigorous aviation safety protocols, these knowledgeable professionals play an important part in providing unrivaled aviation safety standards around the world. Sheet metal technicians are essential for aviation safety, given their critical role in repairing and maintaining aircraft. These skilled technicians not only have expertise in aviation-related sheet metal fabrication and installation, but also the ability to properly read and interpret aviation instructions and procedures.

6. They Perform Many Important Tasks That Keep an Aircraft Safe and Flying Properly

Sheet metal technicians are an essential piece in the aviation industry, performing many important tasks to keep an aircraft safe and operating properly. Their complex skill set involves working with materials including aluminum, steel, stainless steel, and epoxy-fiberglass composite components to fabricate airframes and other aviation-related parts. This includes welding various aviation-specific materials, using manual tools like hammers and shears, as well as more computerized techniques including laser cutting. Additionally, sheet metal technicians also maintain aircraft by inspecting existing structures for any damage or irregularities that need repairing or replacing. With their knowledge and expertise in aviation parts and procedures, they help ensure the safety of each flight. As aviation continues to evolve along with technological advancements in the industry, the need for qualified sheet metal technicians has grown exponentially. Together with other aviation professionals like test pilots and aerospace engineers, these technicians are an integral part of keeping the aviation industry running smoothly for everyone’s benefit.

7. Their Work Is Essential to the Aviation Industry and Helps Keep Air Travel Safe and Reliable

Sheet metal technicians play an essential role in the aviation industry. They fabricate and assemble parts of aircrafts like fuselage and wings, which help maintain a safe and reliable air travel environment. Their work is paramount to the aviation industry because they are tasked with ensuring airtight seals and sound structures that can stand the pressure of flight at higher altitudes. Additionally, these technicians make sure all aviation functional components are set up in accordance with strict safety protocols approved by aviation regulators and industry leaders. In order for aviation operations to continue smoothly, it is vital for sheet metal technicians to stay vigilantly informed about the latest trends in aviation materials and technologies to guarantee a secure flying experience.

In Conclusion

Sheet metal technicians are essential to the aviation industry, helping ensure each aircraft is safe and reliable throughout its flying life. They have expertise in aviation-related sheet metal fabrication and installation, as well as the ability to read and interpret aviation instructions and procedures. Their complex skill set involves working with materials including aluminum, steel, stainless steel, and epoxy-fiberglass composite components to fabricate airframes and other aviation-related parts. Their work is critical in maintaining the high safety standards of the aviation industry, ensuring passengers can enjoy a safe and reliable flying experience each time they take off.